This technology can save a company thousands of dollars in untimely failure, reduction and in some cases, zero downtime, surge of productivity, and universal replacement costs.

Electrical

ARCING

With Arcing, the discharge to ground is a high current pathway across an insulator. This is a “burst of energy” that has a long duration discharge. The “buzzing” Sound that is heard with corona and the initial stages of tracking is not heard with arcing. The “burst of energy” will be seen as wide peaks in the time series.

CORONA

Corona is where the pathway to ground is through the air. This discharge has a buzzing or frying sound that is uniform.

TRACKING

Tracking occurs where there is a low current pathway to ground across an insulator. There is a buildup and discharge of the voltage that produces “popping” sounds. The discharge peaks correspond to the “popping” sounds.

Condition based Monitoring (CbM)*, or the maintenance process where the condition or “health” of a machine is monitored for the earliest signs of impending failure, is how thousands of plants worldwide are saving billions of dollars annually. Early predictions of machine illness is essential to reducing energy waste and eliminating downtime while increasing production output as well as asset availability. Establishing an effective predictive maintenance program that utilizes powerful and accurate technologies such as Ultrasound and Infrared, enables maximum profitability through the ability to see and hear areas of concern we never could before – with precise, timely results, granting an enormous advantage over standard predictive maintenance practices.

Bad Bearings and Misalignments*:

As is often the case during inspection, several machines may appear to be running fine. However, when checked closely you may notice quite a bit of vibration or other causes of alarm. Infrared inspection may show a bad misalignment, indicating inboard bearings are hot and the center of the coupler is showing heat where it should not be warm at all. After seeing this problem through infrared, ultrasound could quickly hear the problem in both inboard bearings. This allows inspectors to immediately act on the concern with the justification that both detection tools found fault within the system.

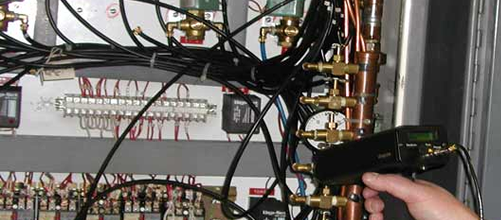

From loose or dirty connections where an infrared camera can detect areas of concern through heat discoloration while ultrasound hears arcing in the loose connection, to loose fuse clips where ultrasound tracks the looseness of the fuse and infrared can detect that the fuse clips have lost tension or where the wire on the fuse appears loose, both technologies compliment each other in several ways – helping inspectors determine the most appropriate next steps, whether trending and reporting over time or immediate part adjustment or replacement.

Steam Trap Case Studies*:

Chevron USA, Perth Amboy NJ has six to eight thousand steam traps throughout the plant. The plant generates close to 500,000 lb./hr. of steam. A steam trap audit with ultrasound and infrared revealed the trap failure rate was up to 28%. Because of this discovery, the refinery has increased its steam trap reliability by 15% within two years after ultrasound technology was put into use as a compliment to infrared. The reduction in steam losses is saving at least $50,000 a month.

Compressed Air Leaks- Going Green-the color of monetary anti-waste*:

Billions of dollars are lost every year when calculating total energy waste. In fact, last year it was estimated that $3.2 billion dollars were lost due to poor energy conservation through compressed air leaks alone. Another way of relating that figure and what most companies don’t realize is the total profit loss from compressed air leaks can amount to 40% of their electric bill. When taking those numbers into perspective, a large percentage of those figures could have been eliminated and utilized as company profit with the combined technology of ultrasound and infrared.

There is yet another up side to the use of ultrasound and infrared technologies. It’s a way for organizations to “go green”. In addition to adding to the benefit of monetary increase, the conservation of energy is a global health necessity, especially now with the political upheaval that is stirring in regards to global warming. By initializing combined technologies of ultrasound and infrared there is a significant energy waste decline, which is an environmental effort to control the amount of wasted fuels, and control conditions that are presenting themselves as alarming hazards.

(*http://www.uesystems.com/new/resources/articles-and-announcements/the-power-of-two-infrared-ultrasound-cbm-technologies/)

NJInfrared.com is a member in good-standing of the United Infrared Network, which is the largest network of multi-disciplined infrared thermographers in the world. As a member, we receive support for our customers from industry experts with decades of combined experience.